Interesting Tech Projects

Posts tagged endmill

Google Sketchup and Kerkythea – A Perfect Combination

Dec 12th

Google Sketchup is pretty nice. I’ve tried 3D CAD programs in the past but never really invested the time to climb the steep (for me) learning curve. There was a bit of a learning curve with Sketchup, but once I got into the “right” way of thinking it became easy to use. Now I use Sketchup all the time, from drawing diagrams for my CNC hobby, to modeling home projects.

The one problem with Google Sketchup is, well, the output looks like a sketch. But now I’ve found a free renderer that not only has a plugin for Google Sketchup, but is just as easy to use as Sketchup. It’s called Kerkythea.

Install, run, and follow the quick start tutorial and you will be rendering your Sketchup models in less than a hour.

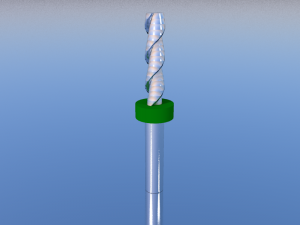

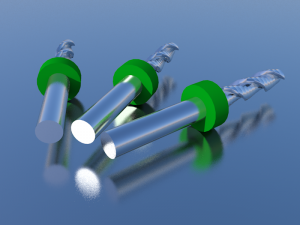

I recently decided to try and model and render some sprial up-cut and down-cut end mills in Sketchup. The results are below.

Introduction to End Mills

Sep 23rd

The best introduction I have found is from the Enco catalog. Fortunately you can view the catalog online. The introduction covers materials, types, number of flutes (including the trade offs), end cut type, shank type and surface treatments.

View the introduction at:

http://www.use-enco.com/CGI/INPDFF?PMPAGE=123

Note that this gives you page 123. Enco’s next release of the catalog may change the location of this introduction to another page. If you see this link is out of date please let me know the new page number.

CNC Cutting Speeds II

Sep 15th

Recently I wrote about the steps I took to reduce the cutting time of a particular part from 67 minutes down to 20 minutes. I have now purchased a couple of 1/8″ four flute endmills from Enco.

I can now cut the 1/8″ wide groove in the design, plus the outer profile with holding tabs much more quickly. In addition I can use the 1/8″ bit to perform a quick roughing pass on the pocket operation. Once complete I switch to the 0.0571″ endmill and make a finishing pass around the edges of the pocket, increasing the detail.

The new time, including the manual tool change, is about 10 minutes. Not bad. At the end of the cutting process the motors, stepper driver chips, transformer and dremel are all a lot cooler.

One small downside is that the 1/8″ bit make a lot of noise.