Interesting Tech Projects

Posts tagged diy

Halogen Reflow Oven Using Off-the-Shelf Parts

Dec 28th

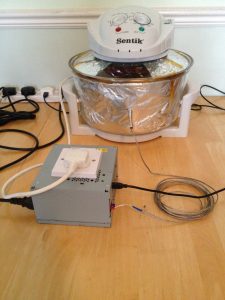

Here is my version of a solder reflow oven for surface mount PCBs. It is a merging of the following two projects, taking advantage of cheap and easy to obtain halogen ovens and off-the-shelf control hardware, avoiding the need to create custom electronics.

- https://apollo.open-resource.org/mission:resources:picoreflow

- http://andybrown.me.uk/2014/05/11/awreflow/

The halogen oven part of the build is identical to Andy Brown’s build. Same oven, same thermocouple, same modifications (remove fat spatter shield, modify fan, install thermocouple).

The software uses picoReflow on a Raspberry Pi Zero W (which has built-in wifi). I have made some improvements to the software which you can obtain from github here: https://github.com/ajayre/picoReflow

- Performs trimmed mean averaging on the temperature values to allow use of noisy thermocouples

- Retries failed MAX6675 connections so it works at power on reset from /etc/rc.local

- Added a temperature compensation offset

- Removed check for sudden temperature increases (allows PID step and bump tests)

- Uses PID with 2Hz PWM taken from Andy Brown’s code

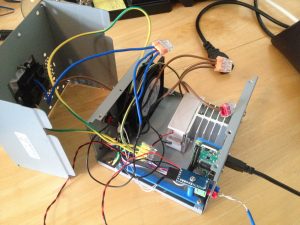

I made some changes to the power/control system. Like Andy Brown I used an old desktop PC PSU case. I removed everything from it except for the power connector. Into the case I put:

- SSR relay and heatsink

- 240V 80mm case fan

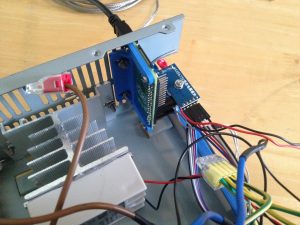

- Raspberry Pi Zero W

- MAX6675 thermocouple IC

The connections are very simple. The relay and the fan are connected to 240V. The MAX6675 is connected to the Raspberry Pi and the Raspberry Pi controls the relay. The fan is always on when power is applied.

I also added a push button connected to a Raspberry Pi GPIO. When pressed it runs a simple python script that shuts the Raspberry Pi down cleanly.

I 3D printed a couple of brackets to mount the electronics in the case – they are blue in the pictures. In order to connect the Raspberry Pi to a USB cable for power I removed part of the grille.

I am initially testing with lead-based solder, so I copied the reflow profile from here:

Low Cost CNC Milling Machine

Oct 4th

The primary purpose of this blog is to document specific technical projects that I will have a go at. First up is an attempt at building a low cost but precise CNC milling machine. I will follow the design by Tom McWire shown here: Easy to Build Desk Top 3 Axis CNC Milling Machine.

So now you are wondering, why bother if how to build this machine has been described on the internet already? Because my aim is reproduceability and accuracy. The problem right now is that if two seperate people decide to each build a machine from the instructions, they will end up with slightly different machines that perform differently. For example the dimensions of the machine and which stepper motors used are missing. I want a set of instructions that people can follow to yield predictable results.

Also missing is a description of the kind of accuracy that can be expected. At this point I am not sure if this machine can generate an accuracy good enough for my needs. Hopefully it will. If I can figure out what design decisions to make to achieve the accuracy I need, and document them, then other people will know up front exactly what they need to do to also get the same accuracy. My aim is to be able to engrave commemorative coins. These coins have a small area where a name can be placed, and this will require precision.

I hope to also make some minor improvements here and there, and it might involve a few iterations before the machine works well enough. One of Tom McWire’s aims was to build it in less than $200. I also have the same aim, but if a situation arises where I can spend a few dollars more to increase precision then I will do it. For example I won’t be getting old motors from printers because they are all different and someone else cannot then come along and follow my instructions to get the same machine. Instead the specifications of the motors I use must be known.

(picture from Easy to Build Desk Top 3 Axis CNC Milling Machine)