Interesting Tech Projects

Halogen Reflow Oven Using Off-the-Shelf Parts

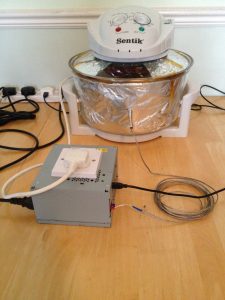

Here is my version of a solder reflow oven for surface mount PCBs. It is a merging of the following two projects, taking advantage of cheap and easy to obtain halogen ovens and off-the-shelf control hardware, avoiding the need to create custom electronics.

- https://apollo.open-resource.org/mission:resources:picoreflow

- http://andybrown.me.uk/2014/05/11/awreflow/

The halogen oven part of the build is identical to Andy Brown’s build. Same oven, same thermocouple, same modifications (remove fat spatter shield, modify fan, install thermocouple).

The software uses picoReflow on a Raspberry Pi Zero W (which has built-in wifi). I have made some improvements to the software which you can obtain from github here: https://github.com/ajayre/picoReflow

- Performs trimmed mean averaging on the temperature values to allow use of noisy thermocouples

- Retries failed MAX6675 connections so it works at power on reset from /etc/rc.local

- Added a temperature compensation offset

- Removed check for sudden temperature increases (allows PID step and bump tests)

- Uses PID with 2Hz PWM taken from Andy Brown’s code

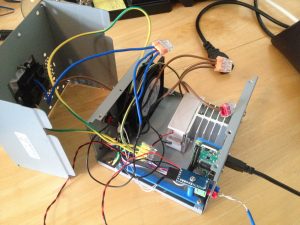

I made some changes to the power/control system. Like Andy Brown I used an old desktop PC PSU case. I removed everything from it except for the power connector. Into the case I put:

- SSR relay and heatsink

- 240V 80mm case fan

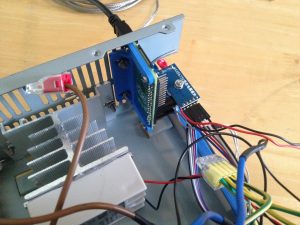

- Raspberry Pi Zero W

- MAX6675 thermocouple IC

The connections are very simple. The relay and the fan are connected to 240V. The MAX6675 is connected to the Raspberry Pi and the Raspberry Pi controls the relay. The fan is always on when power is applied.

I also added a push button connected to a Raspberry Pi GPIO. When pressed it runs a simple python script that shuts the Raspberry Pi down cleanly.

I 3D printed a couple of brackets to mount the electronics in the case – they are blue in the pictures. In order to connect the Raspberry Pi to a USB cable for power I removed part of the grille.

I am initially testing with lead-based solder, so I copied the reflow profile from here:

| Print article | This entry was posted by Andy on December 28, 2017 at 4:27 am, and is filed under Electronics. Follow any responses to this post through RSS 2.0. Both comments and pings are currently closed. |

Comments are closed.

about 7 years ago

picoreflow isn’t a british idea though

about 7 years ago

I never said it was. I hope you incorporate the changes from my fork.

about 7 years ago

That domain name implies it If you’d send a PR with your changes I most certainly wouldn’t reject it like some other GH projects do. Some changes may not be compatible with the more general approach of picoreflow though.

If you’d send a PR with your changes I most certainly wouldn’t reject it like some other GH projects do. Some changes may not be compatible with the more general approach of picoreflow though.

I think everything that makes it more stable and deals with noise/TC issues is worthy of merging into picoreflow codebase. I was gonna have a look at the changes you’ve made and cherry pick if I ever find the time :/

about 7 years ago

There is a link right at the start of the post that goes to the picoflow project, so I think where it comes from it is pretty clear.

about 6 years ago

Shouldn’t the software be trying to follow the curve? My toaster oven is slow to heat up so the program completes way before it even gets to temp . Suggestions?

about 6 years ago

Your toaster oven is probably not suitable for doing this.