Interesting Tech Projects

Using Alibre Design for Multi-color and Multi-material 3D Printing Part II

Previously I wrote about my little utility that allows exporting properly positioned STLs from Alibre Design so they can be imported into a slicing program for multi-color printing. This is fine for use with the RepRapPro slicer but perhaps not with other slicers.

Slic3r is a very popular, fast and flexible slicing program and now it also supports printing multi-color objects. The file format chosen by it’s author is AMF – Additive Manufacturing File. It is essentially a way to group STL files together into a single object and specify different colors or materials for various parts.

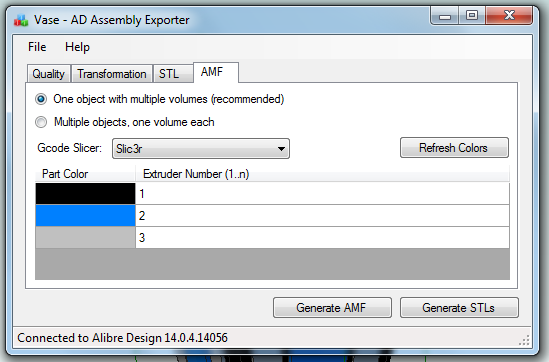

I’ve now updated my exporter utility to support saving Alibre Design assemblies directly to this format:

When an assembly is opened the application obtains the colors used by the parts in the assembly. It is then possible to assign the colors to extruders on the 3D printer. For example in this image black is the body of the object and has been assigned to the primary extruder. It’s necessary to choose which slicing program is being used as there isn’t a standard way of mapping colors to extruders. In particular Slic3r currently has several limitations so by choosing Slic3r the application will stop you from making invalid choices.

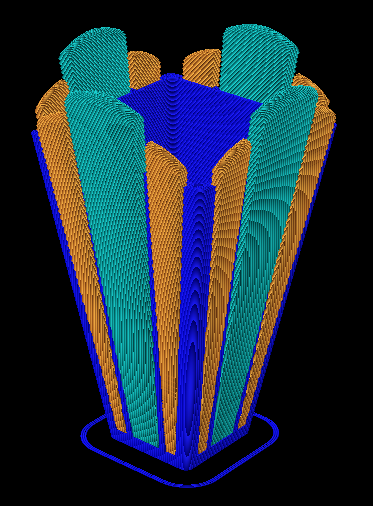

Once generated the AMF file can be loaded directly into Slic3r and sliced. Here is the g-code output shown in Repeiter-Host:

Note that the colors don’t match the Alibre Design assembly because Repetier-Host uses it’s own coloring scheme to represent the different extruders. For example blue is always the first extruder.

Now the object is ready to be printed. The estimated print time for this example is five hours and 45 minutes.

| Print article | This entry was posted by Andy on February 27, 2013 at 10:28 am, and is filed under 3D Printing, Software Engineering, Windows. Follow any responses to this post through RSS 2.0. Both comments and pings are currently closed. |

No comments yet.

Comments are closed.